About Us

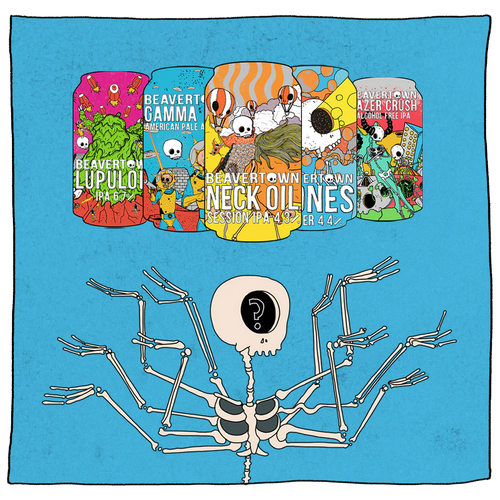

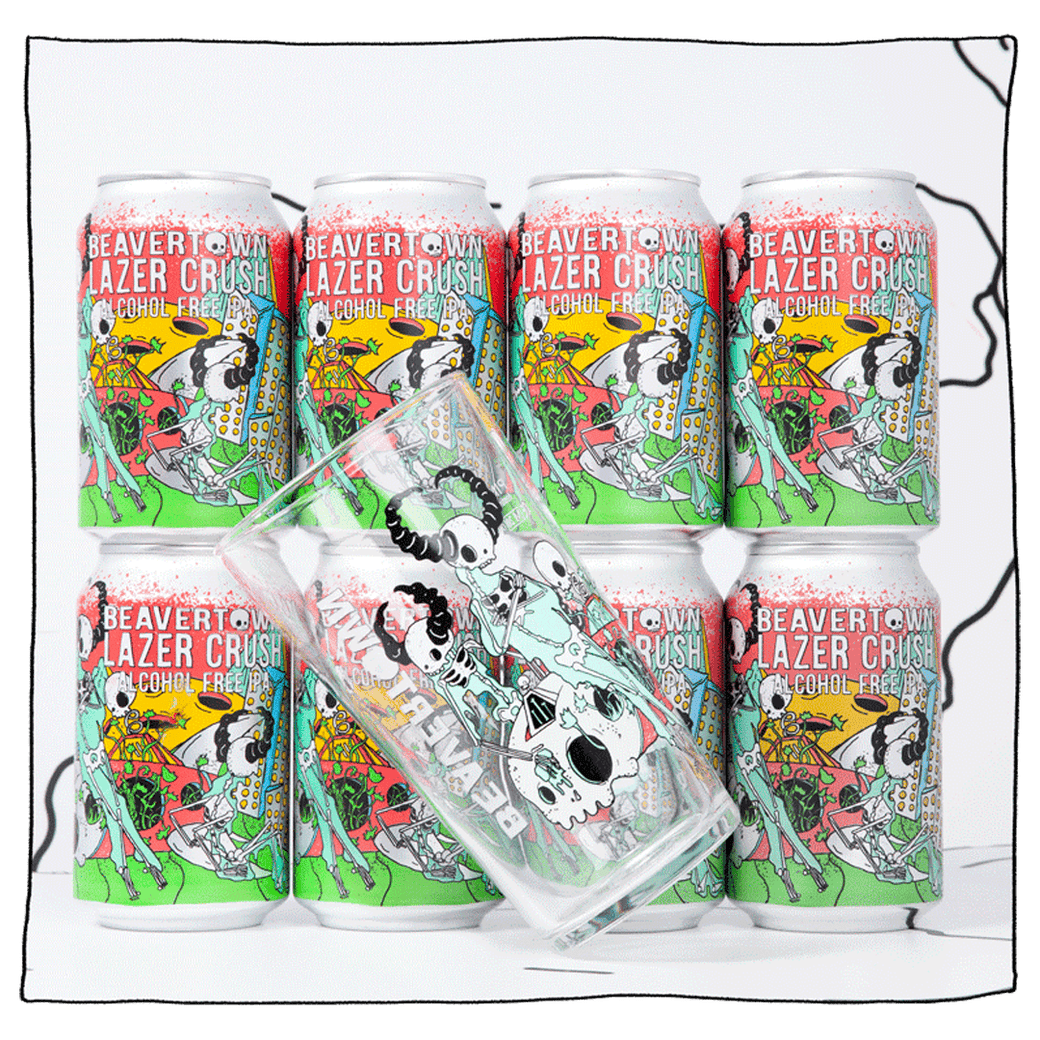

Beavertown. Out of This World Beer. Drank on Earth.

Over 10 years ago, something crash landed in the kitchen of a North London grill joint and Beavertown was born.

Now, we’re happily brewing loads of great beer - for everyone to enjoy - anywhere in the universe...although tastes best when drank on Earth. So, if you’re after some tasty beer with a difference you’ve come to the right place.

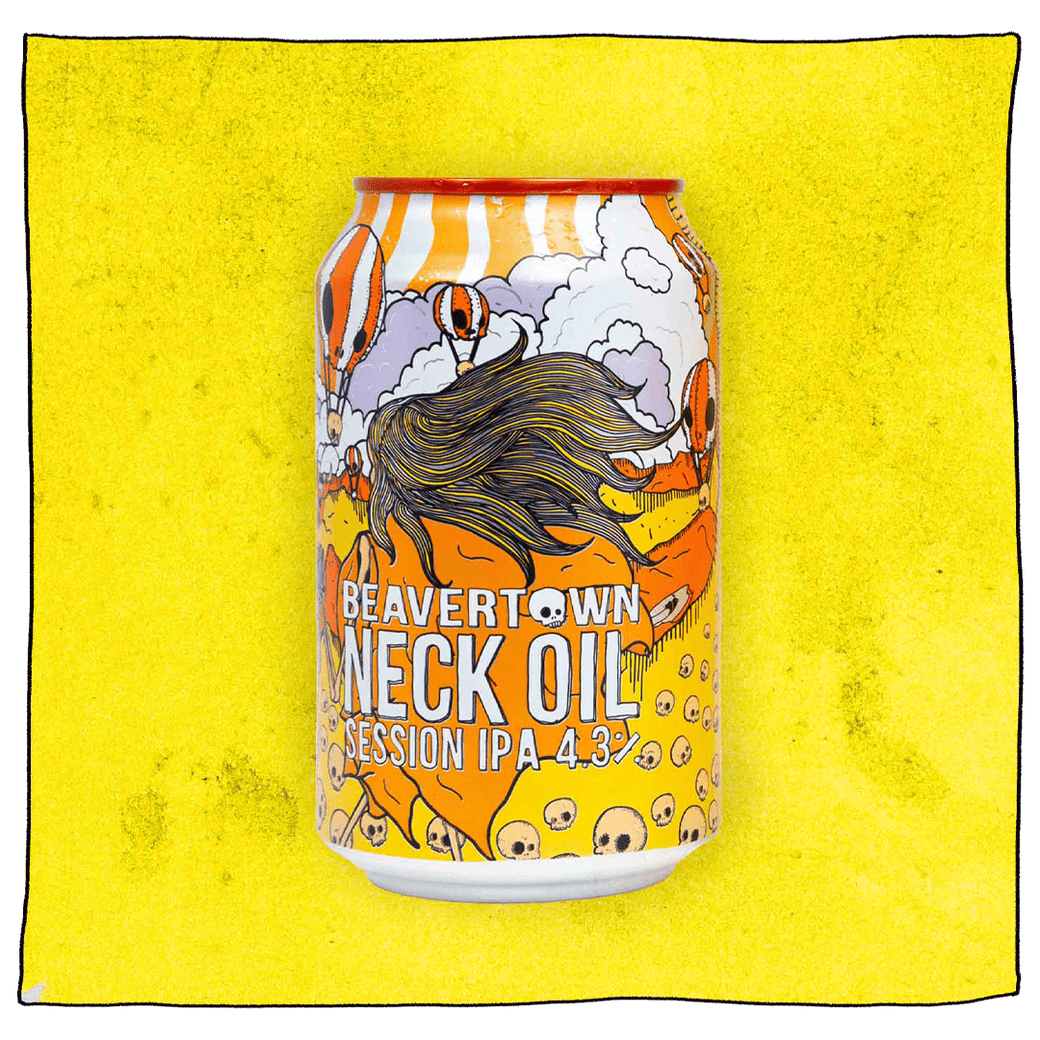

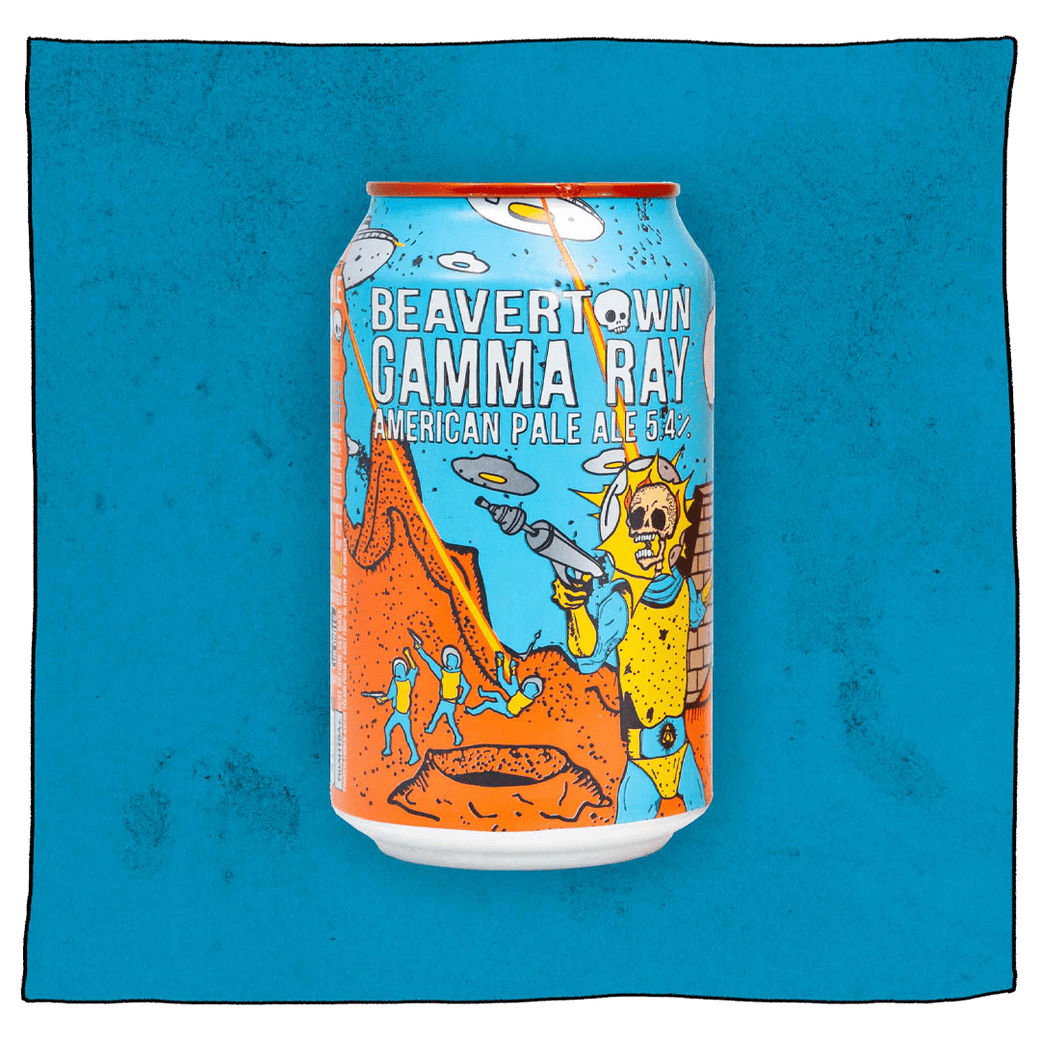

Discover our award winning and easy-drinking Neck Oil, the bold and characterful Gamma Ray and many more at Beavertown Brewery.